Aircraft Prototyping & Manufacturing

DARcorporation can design, analyze and build the structure, whether it is made out of composites, metal or a combination of both. We will select materials and provide layup schedules for composites. We will analyze strength, stiffness, elastic stability, flutter and overall system dynamics.

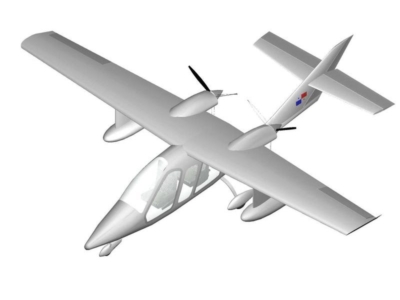

DARcorporation engineers have worked with many unconventional designs including experimental airplanes, flying cars and UAVs. Our designs are optimized for best performance based on results from CFD, structural analysis and wind tunnel testing. In addition to designing your vehicle, we will keep us in close involvement in every step of its fabrication and assembly, thereby assuring that “what we designed is what you fly”.

We can perform static load, dynamic normal modes, flutter and flight tests to ensure that your airplane does what we say it will do.

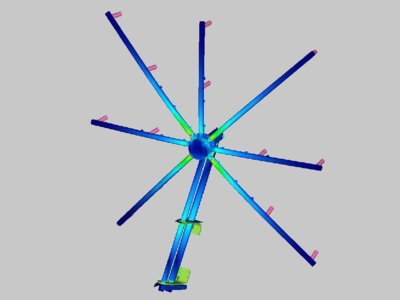

DARcorporation uses a stereolithography (SLA) 3D printer for prototyping unmanned aircraft systems (UAS) propellers and other small parts. The use of this 3D printer decreases the design time required for small UAS propellers by reducing the fabrication time from a week to a day, giving us the ability to fabricate designs and have them installed on our in-house small UAS propeller test stands the next day. The 3D SLA printer allows us to keep a majority of our 3D printed parts and designs in-house instead of collaborating with other 3D print shops and having to wait weeks for parts.

Projects in Aircraft Prototyping & Manufacturing

Services Include:

Proposal and Rates

Please Contact Us for additional information or a detailed proposal. Your detailed proposal will include cost, calendar schedule and estimated man-hours per task. This will be provided at no cost or obligation. We look forward to hearing from you!